Keith Pickersgill

Q-Bond remains the best option for Carbon Fibre props. It is the same density as Carbon, hence no need to

re-balance the prop if you do a careful repair. Easily worked with a file,

sandpaper or my personal favourite, a Dremmel. In some cases, gentle

application of an angle-grinder or bench-grinder can be used for the first prep

before changing to something less drastic. Finish off with 1200 grit

water-paper and polish on a piece of leather, delivering a perfect finish.

For wooden props, Epoxy is best. Either the two-part

quick-set Clear epoxy (Prattleys, et-el), or the UV activated version such as

Anthony's Dura Rez (and many similar brands).

Unfortunately Epoxy is a VERY different density to

Carbon, so most epoxy repairs would require extensive re-balancing on Carbon

props, though its good for filling very small cavities in Carbon.

Some tips: With the UV activated resin, work indoors (or

in the shade under a tree if outdoors), then when you have the resin just where

you want it, step out into the sunlight to cure. You could partially cure in sunlight for say

30 seconds, then step back into the shade to check and adjust, and repeat as

often as required if you want a perfect job.

For Q-Bond, the liquid part is ordinary super-glue. Even

the cheapest superglue from Chinatown outlets works just as well. For tricky

jobs, get the slow-set Gel-type superglue, which allows you to form and re-form

the carbon black powder as it cures gradually.

You will always run out of the superglue before running

out of the Q-Bond Carbon Black, so buy a few very small tubes (3g) of superglue

to add to your toolkit, at about R5.00 each from Chinatown or similar outlets.

Once opened, you usually can discard a bottle of superglue unless you keep it

in a fridge or keep it perfectly upright in storage.

To fill a big hole in a hollow carbon prop, take the

thinnest tissue paper you can find (one layer of 2-ply works well), stuff it

into the hole and tease it to form the shape you want, then very gently wet the

tissue with superglue. Wait for it to dry and become rigid, then re-wet small parts

at a time and apply the Q-Bond Carbon Black in very thin layers.

Build the Q-bond to slightly proud, then grind/file/sand

down to shape then polish.

The Q-bond bottle usually has a HUGE hole, too big for

prop repairs. Instead of screwing off the cap, I drill a 2mm hole in the cap

and spinkle gently out of that, covering the hole after the job with some

Gaffer's Tape (or Duct Tape or even Masking Tape will do).

A quick and easy way to re-balance spanwise, is to add a

sticker (decal) to the lighter blade.

Remove the backing paper and lay it upside down on the

blade (i.e. sticky side away from the prop). While the prop is on the balancer,

slide the decal along the blade until it is balanced.

Closer to the hub if the decal is too heavy, or closer to

the tip if you need more weight. Once it looks level, flip the decal over and

stick it down in that spot. Now rub the decal very hard around the edges,

especially the leading edge, with the back of your fingernail to activate the

pressure-sensitive adhesive, to prevent it from lifting off in flight.

If a prop needs balancing chord-wise, i.e. it rolls over

to one side on the balancer, then you have a tough time ahead to balance it, as

you have very little radius to work with. This is why you want to repair very carefully,

with a product of similar density to the original prop.

In this case, the best is to use clear spraypaint, and

lay down a layer all down the lighter edge, which is down one blade's leading

edge, and the other blade's trailing edge.

Wait for it to dry, check the balance, and repeat as

required.

Unfortunately you affect the airfoil a but, but that is

the lesser of two evils, as an unbalanced prop causes much damage to your

engine and framework.

Vibration eventually makes aluminium and stainless-steel

brittle, then the frame cracks on all the welds. So take your time to balance

the prop as accurately as possible.

On wooden props, you can drill a 10mm hole on one side of

the hub, roughen the surface inside the hole, fill it with molten lead, then

re-check the balance. If too heavy, center-punch the lead plug, then start

drilling the lead away with a 6mm bit, until the prop is balanced.

I have seen some pilots drill and cut a 10mm thread into

the hole, then screw in a short bolt or capscrew as a weight, until the find

the perfect balance, then epoxy the bolt into place.

It looks a bit strange but it works, but I prefer molten

lead, as a wood thread is not robust enough for my liking. If you don't want to work with hot lead, then

use fine lead buckshot, and epoxy into place in the hole.

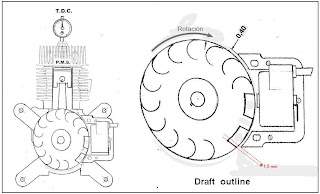

Make sure your choice of propellor balancer can check the

balance in both the span and chord

directions. This

requires that the prop lays flat in/on the balancer, not edge-on.

Either the popular old Prop-Top

or my new favourite, the Gadgeteer Benchtop Balancer

Those knife-edge types or any that holds the prop

edge-on, can check only the span and not the chord balancing.

Both Q-bond and Epoxy can be carried in your harness

pocket, along with a sanding sponge for emergency field repairs.

Keith Pickersgill